-

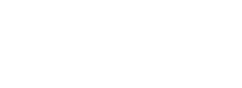

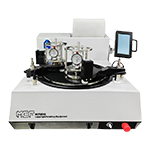

The two-fluid cleaning technology applied to build the nano-scale two-fluid cleaning structure,with the DIW and N₂ flow rates adjustable according to the process requirements

-

The intelligent process control system integrates PLC+PC control,manual and automatic switching,allowing the quality of the brushed wafer to be recorded

-

Powerful data storage function,allowing machine LOG information to be stored and retained for 6 months; process recip can be edited and stored at least 100 pieces

-

Dry-and-wet separation,a composite drying system that uses spin drying and lamp drying composite method to dry wafers

-

Continuous transfer of 1,000 pieces without failure,with the processing breakage rate being less than 1/5000

-

The machine inspection can observe the full path of the wafer

-

Any part of the machine needs to be easily disassembled for later maintenance

-

Equipped with wafer and cassette correct position detection and alarm system

Please Leave Us a Message on the Right

Please Leave Us a Message on the Right