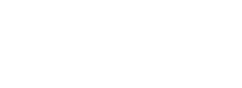

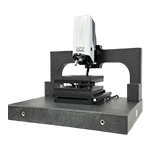

In the wave of transformation of the energy-saving light source industry to high brightness and low energy consumption, lapping and polishing machines have become the core tools for the manufacture of LED, OLED and quantum dot light-emitting materials.

In view of the strict requirements of organic optoelectronic materials such as Alq3 and PPV for nano-scale surface flatness, the high-precision lapping and polishing machine realizes the luminescent layer through multi-axis linkage control and nano-scale abrasive ratio technologyThe thickness error ≤ 0.1 μmbreakthrough processing.

在量子点显示面板生产中,其独创的盘温监控调节功能可同步完成衬底减薄与表面活化,使蓝光激发效率提升40%,色域覆盖率达110% NTSC。对于大尺寸OLED照明基板,设备搭载的多分区压力控制系统将表面粗糙度稳定控制在0.5nm以内,显著降低微腔效应损耗。

该技术在Mini LED背光、柔性照明器件等领域的应用,推动行业良率突破98%,单位能耗下降30%,为绿色光电制造树立新标杆。

Please Leave Us a Message on the Right

Please Leave Us a Message on the Right