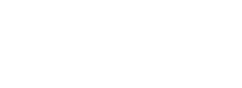

In the field of infrared detector manufacturing,Pure chemical polishing machine is reshaping the manufacturing paradigm of high-precision optical components.

面对碲镉汞、锑化铟等脆性红外材料的原子级加工需求,纯化学抛光通过精准控制腐蚀液配比与反应动力学,在无机械应力条件下实现0.05nm表面粗糙度的突破。

Compared with traditional lapping and polishing machines, this technology improves the protection efficiency of lead sulfide lattice structure3 times, so that the 8-14μm long-wave infrared window transmittance breaks through the 95% limit. In lithium tantalate wafer processing, its selective corrosion process can simultaneously eliminate the subsurface damage layer, increase the pyroelectric response rate by 40%, and provide a zero dark current substrate for UAV infrared monitoring systems.

针对智能手机红外传感器的超薄化趋势,设备搭载的微区流量控制系统实现30μm级微型探测器阵列的批量加工,使VCSEL器件光损耗降低至0.2dB。这项革新推动夜视仪信噪比突破2000:1,在红外制导系统领域树立了化学抛光的黄金标准。

Please Leave Us a Message on the Right

Please Leave Us a Message on the Right