CZT化学机械抛光解决方案

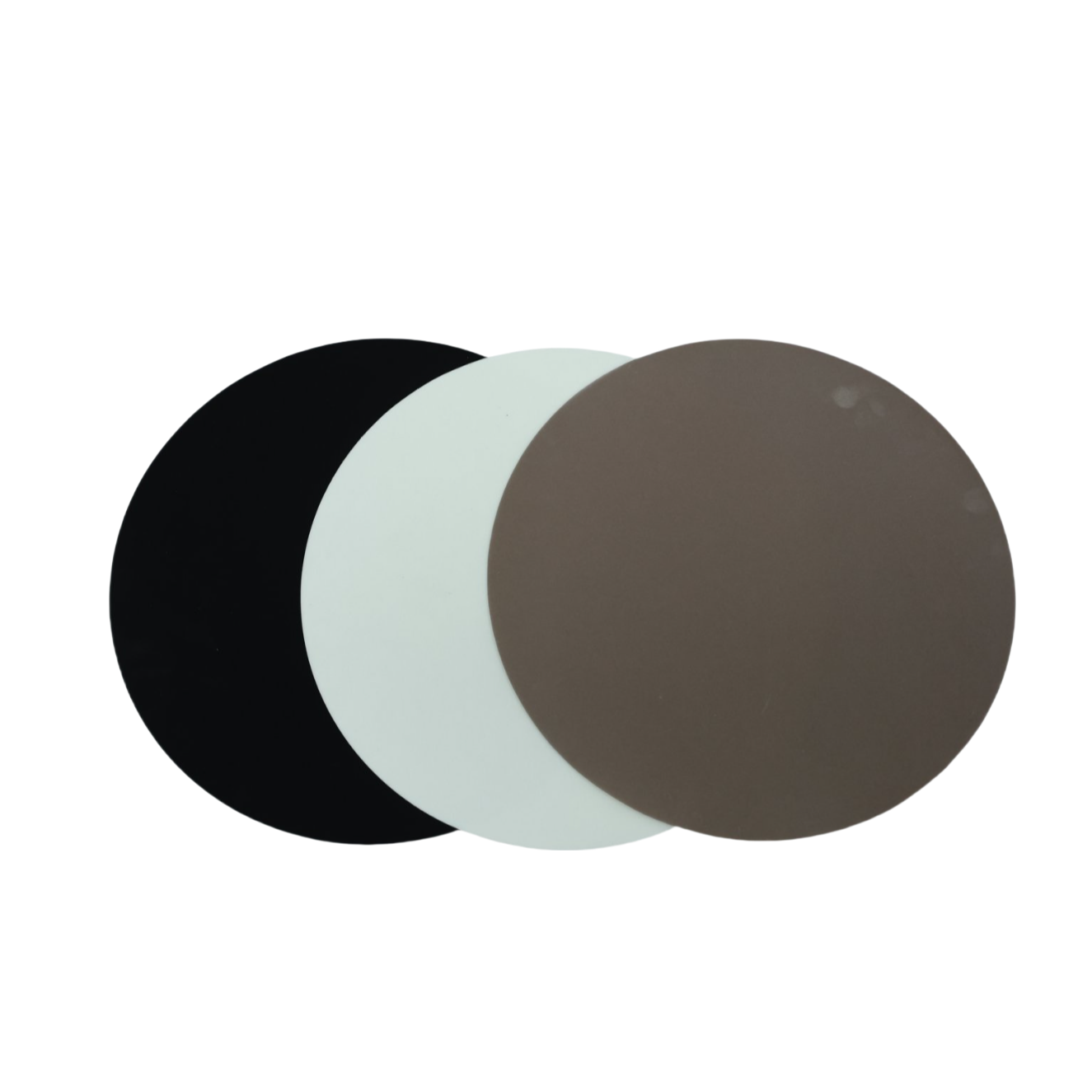

客户样品初始状态:

材料:CZT;尺寸:3寸;形状:圆形;厚度:2000um;粗糙度:200nm;TTV:20um

加工后指标要求:

厚度:1000±10um;粗糙度:≤3nm;TTV:≤4um;无划痕及损伤,同时加工多片

工艺解析:

Step1lapping stage: Using our MP series 8-inch mass-produced equipment, equipped with grooved glass lapping discs, customized three-zone adsorption surface fixture, lapping pressure of 20-40g/cm², rotation speed of 15-40 rpm, alumina powder (particle size 3-10μm) as lapping slurry, removing about 900um material thickness

Step2 Chemical mechanical polishing stage: Using our ML series 8-inch mass-produced equipment, equipped with stainless steel polishing disc combined with soft damping cloth polishing pad, using a special ratio of silica sol chemical polishing slurry, pressure 15-35g/cm², speed 20-50 rpm, can reduce the surface roughness to Ra ≤1nm

Step3 Pure chemical polishing stageUsing our CPI series pure chemical mass production polishing equipment, equipped with customized splint and flannel polishing pad, using the customer's confidential corrosive liquid formula, the pressure is the weight of the carrier and the wafer, the rotation speed is 10-50rpm, and the surface can be treated to a regular crystalline phase state suitable for the growth of epitaxial structures

Case supporting host and consumables:MP series 8-inch lapping mass production machine, ML series 8-inch polishing mass production machine, AMS series gluing machine, CPI series pure chemical polishing machine, alumina lapping powder, special ratio silica sol polishing slurry, white wax, damping cloth polishing pad and flannel polishing pad, etc

Customer feedback: High mass production efficiency, can process 12 pieces of 3-inch wafers at the same time, the chemical polishing machine has super anti-corrosion performance, and the mass production index of the product is stable.

Please Leave Us a Message on the Right

Please Leave Us a Message on the Right