Silicate wafer lapping and polishing solutions

客户样品初始状态:

材料:硅酸盐晶圆;尺寸:6寸;形状:圆形;厚度:1000um;粗糙度:650nm;TTV:40um

加工后指标要求:

厚度:300±5um;粗糙度:≤2nm;TTV:≤8um;无划痕及损伤

工艺解析:

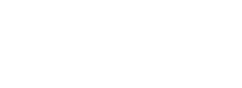

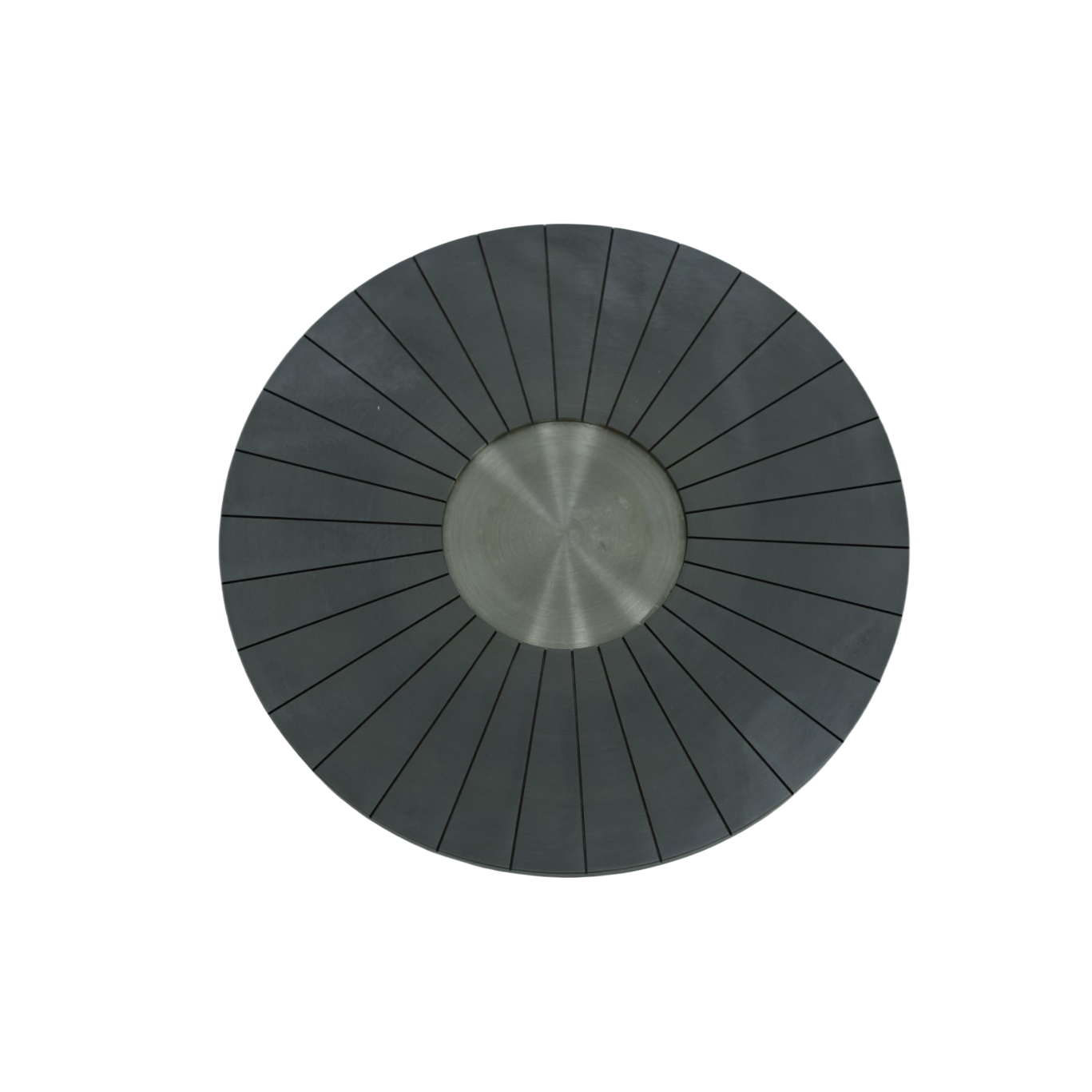

Step1Coarse lapping stage: Using our GNAD-E series glapping and polishing machine, equipped with grooved cast iron lapping disc, lapping pressure 40–80g/cm², rotation speed 25–50 rpm, using diamond slurry (particle size 5–20μm) as lapping slurry for rapid thickness removal

Step2Fine lapping stage: Based on Step 1, the diamond slurry (particle size 1–5 μm) is replaced with a lapping slurry, and the layer thickness of the damaged layer and crush damaged layer is reduced

Step3 Rough Throwing Stage: Using our GNAD-E series lapping and polishing machine, equipped with stainless steel polishing disc combined with rigid foamed polyurethane polishing pad, using alumina slurry (particle size 1-3um), pressure to 30-60g/cm², speed 30-60 rpm, can further reduce the damage layer, and achieve surface roughness Ra ≤10nm

Step4 Fine Polishing Stage: Based on Step3, replace the alumina polishing slurry (particle size 0.2-1 μm) with the polishing slurry, and the final surface Ra ≤ 0.5nm

Case supporting host and consumables:GNAD-E series lapping and polishing machine, grooved cast iron lapping disc, stainless steel polishing disc, AMS series gluing machine, diamond slurry, alumina lapping powder and foamed polyurethane polishing pad

Customer Feedback:The scientific use of the process route and the stable operation process of the equipment have greatly improved the efficiency of material research and development.

Please Leave Us a Message on the Right

Please Leave Us a Message on the Right