Diamond wafer lapping and polishing solutions

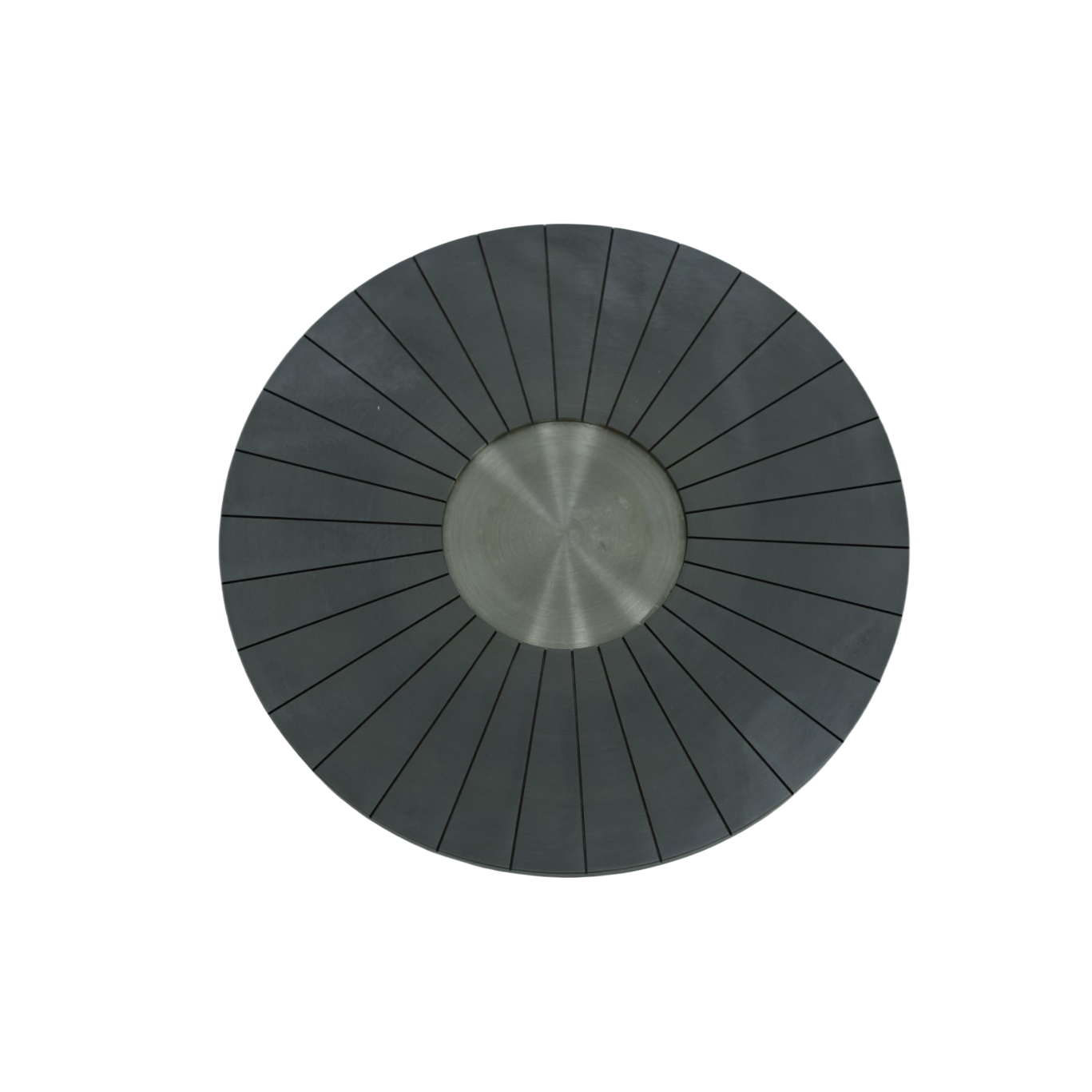

客户样品初始状态:

材料:金刚石晶圆;尺寸:4寸;形状:圆形;厚度:1000um;粗糙度:麻面微米级凹凸表面;TTV:40um

加工后指标要求:

厚度:800±10um;粗糙度:≤50nm;TTV:≤10um

Step1Coarse lapping stage: using our GNAD-E series lapping and polishing machine, equipped with grooved cast iron grinding disc, customized pressurization module, lapping pressure 80-160g/cm², speed 60-100rpm, diamond slurry (particle size 20-50μm) as lapping slurry, thickness removal

Step2Fine lapping stage: Based on Step1, the diamond slurry with a special crystal structure (particle size 1–5 μm) is replaced as the lapping slurry, and the layer thickness of the damaged layer and the crushing damaged layer is reduced

Step3Rough polishing stage: using our GNAD-E series lapping and polishing machine, equipped with stainless steel polishing disc combined with rigid foamed polyurethane polishing pad, using diamond slurry with special crystal structure (particle size 1-3um), pressurized module pressure increased to more than 100g/cm², speed 80-110 rpm, can further reduce the damage layer, and reach the surface roughness Ra ≤100nm

Step4Fine polishing stage: Based on Step3, replace the alumina polishing slurry (particle size 0.2-1μm) equipped with a certain concentration of acid corrosion liquid as the polishing slurry, and the final surface Ra ≤50nm

Case supporting host and consumables: GNAD-E series lapping and polishing machine, grooved cast iron lapping disc, stainless steel polishing disc, AMS series gluing machine, diamond slurry, alumina lapping powder, black wax or yellow wax and expanded polyurethane polishing pad

Customer feedback: This solution solves the pain points that plague us in diamond processing TTV and roughness.

Please Leave Us a Message on the Right

Please Leave Us a Message on the Right