Lithium niobate modulator face lapping and polishing solution

客户样品初始状态:

材料:铌酸锂结构件;尺寸:10mm*20mm;形状:方形,长宽有参差;厚度:500um;粗糙度:端面切割痕迹,呈现断崖形貌

加工后指标要求:

形状:两端面磨抛后宽度(10mm方向)差小于50um,总移除宽度<1mm;粗糙度:≤1nm;端面8°角倾斜

工艺解析:

Step1End face lapping alignment stage: using our GNAD-P series equipment, using customized fixtures and 8° angle tilt fixture attachment clamping, equipped with flat glass lapping discs, the total pressure of the end face is ≤ 200g, the speed is 10-30 rpm, and the alumina powder (particle size 3-9μm) is used as the lapping slurry to align and grind the end face, and the thickness is removed 400um

Step2End face fine lapping stage: Based on Step1, replace alumina powder (particle size 1-3um) with fine lapping slurry, and the processing effect has no end face cracking traces, and the roughness can reach Ra≤100nm at this time

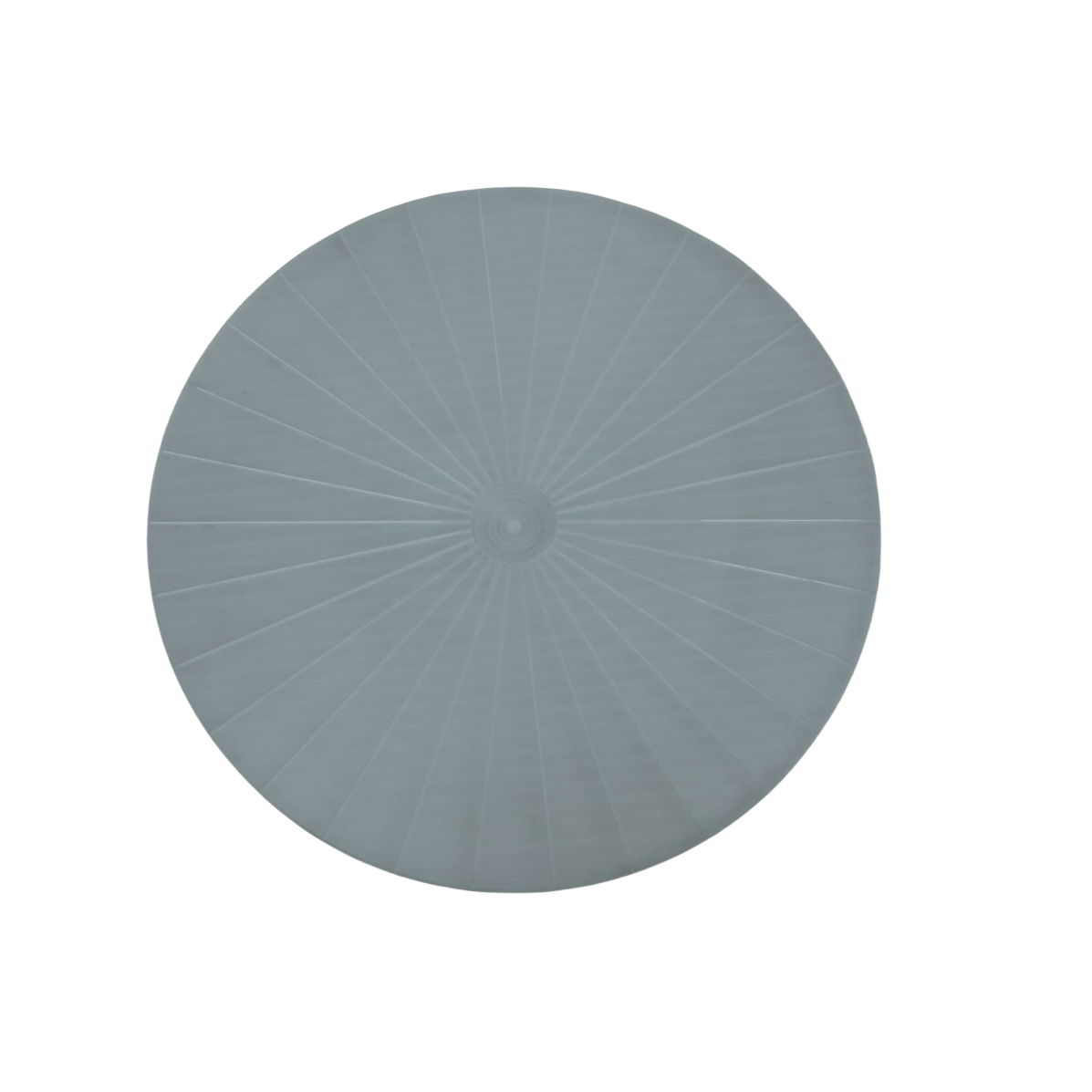

Step3Precision polishing stage: using our GNAD-P series equipment and its customized fixtures and accessories, equipped with stainless steel polishing disc combined with special damping cloth polishing pad, the total load bearing of the end face ≤ 150g, the speed of 5-20rpm, the selection of silica sol polishing slurry or cerium oxide polishing slurry (particle size 0.1-1um) as the polishing slurry, the roughness of the polished end face reaches Ra≤1nm

Step4-6 Polishing the second end face: Polishing the second end face in Step1-Step3 steps to achieve the same effect as the first end face

Case supporting host and consumables: GNAD-P series equipment, heating plate, customized fixtures and fixture accessories, alumina lapping powder, silica sol polishing slurry and polyurethane polishing pad, etc

Customer feedback: The end polishing needs of multi-form lithium niobate modulator surface materials and bulk materials were quickly realized, and the end face light loss was reduced to the design standard.

Please Leave Us a Message on the Right

Please Leave Us a Message on the Right