来源:人工晶体学报

目前,蓝宝石抛光行业主流采用的仍是纳米二氧化硅作为抛光液,最后得到抛光表面的粗糙度(Ra,原子力显微镜测试)均在0.3nm以下。在抛光过程中,二氧化硅抛光液与蓝宝石表面的反应如下式所示,产物是硅酸铝的二水化合物。Al2O3+2SiO2+2H2O=Al2Si2O7·2H2O

Although aluminium oxide abrasive can be used as a sapphire polishing slurry, it is difficult to obtain aluminium oxide with good uniformity and nanometer size because the aluminium oxide abrasive produced now is generally obtained through calcination, lapping and screening. The most lethal is the high hardness of aluminum oxide, and the scratches on the polished surface are serious; The viscosity is large, and the polished surface is not easy to clean, and it is difficult to ensure the surface flatness of the polishing material. Although it has been reported that aluminum oxide is used as a polishing slurry, it is currently only in the experimental stage, and the main problems are: (a) the high speed requirements for the equipment; (b) The surface roughness of sapphire is relatively large; (c) slightly more surface defects; (d) Higher cost. Abhaya K. Bakshi and others in the United States use α or β-type silicon carbide polished sapphires with a particle size of 100~400nm. They used a silica coating to soften the surface of the silicon carbide in an effort to reduce surface scratches on the sapphire. The reason for this is that the silica coating can passivate or reduce the sharp corners of the silicon carbide particles. The core of the particles is still the harder silicon carbide, and the abrasive maintains a better polishing removal rate. They also use a composite polishing slurry of silicon carbide and silicon dioxide (30% SiC, 70% SiO2) to process R-oriented sapphires, which can increase the polishing rate by 30%~50% compared with silica polishing slurry without adding silicon carbide.

在二氧化硅抛光液中加入催化剂(Fe-Nx/C)可以提高蓝宝石的抛光速率,提高幅度约为15%;该催化剂含有三氧化二铁、四氧化三铁、吡啶型氮、吡咯型氮。利用超声波的振动能显著提高SiO2硅溶胶抛光蓝宝石过程中的去除速率(约3.8倍),并且粗糙度有所降低。超声波是加在单面抛光机的抛头上的。可能解释的原因是:(1)二氧化硅颗粒在蓝宝石表面的运动路径加长了;(2)二氧化硅颗粒与蓝宝石的接触压力提高了;(3)超声波的振动和气蚀作用,加强了二氧化硅颗粒与蓝宝石表面的作用。

目前,蓝宝石材料的晶向一般是C向,因蓝宝石材料硬度较大,化学活泼性差,与抛光其它材料相比,其抛光速率相对比较慢。目前,国际上蓝宝石的一般抛光速率不超过5~10μm/h。河北工业大学宗思邈、刘玉岭在实验室利用自主研发的抛光液在高pH值,约为12.5、高磨料浓度(50%)以及快速将抛光温度升至45℃,蓝宝石抛光速率可达11.3μm/h。大连理工大学的李树荣、金洙吉研究了不同的pH调整剂对抛光速率的影响,比较了氢氧化钠、氢氧化钾、氢氧化钙和氨水四种无机碱,发现氢氧化钾能明显提高蓝宝石的抛光速率。河北工业大学于江勇、刘玉岭在研究中将纳米级的氧化铝颗粒(浓度为2%)加入到SiO2抛光液中,可以将蓝宝石的抛光速率从9μm/h提高到11.3μm/h,且二氧化硅抛光液的稀释率从1∶1提高到1∶2。除了抛光设备之外,影响抛光速率的主要因素是抛光液。此外,和C向蓝宝石相比,A向、M向、R向的抛光速率更慢。可能的原因是C向蓝宝石晶体方向是(0001),且原子键合是O-Al-Al-O-Al-Al-O;M向和A向蓝宝石晶体方向分别是(10-10)和(11-20),他们的化学键合是Al-O-Al-O。因为Al-Al比Al-O键能小且键合要弱,C向蓝宝石的抛光主要是将Al-Al键打开,故抛光速率相对较快。研发多系列的高效蓝宝石抛光液显得尤为迫切。

抛光工艺分为单面抛光工艺和双面抛光工艺。关于蓝宝石的平整度(TTV)和弯曲度(WARP)指标,一般而言,双面抛光设备加工出来的蓝宝石晶片要比单面设备加工的蓝宝石片好,主要由双面抛光的原理所决定的。在直接双面抛光过程中,晶片可以实现自转及大范围的公转。这样,抛光出来的片子的平整度要好。另外,在直接双面抛光过程中,实现了正面和反面受力均等、同步抛光,因此,蓝宝石片子的弯曲度要好。

随着对最终蓝宝石产品的质量要求越来越高,表面质量的要求也随之提高。蓝宝石表面质量的好坏,除了取决于最终的湿法化学清洗,抛光结束前的最后一步的轻压抛光(buffingpolish)亦非常重要,往往被忽视。轻压抛光的特点是轻压、转速快、时间短。轻压抛光完成得好,可以降低表面粗糙度、减少表面缺陷。

- HOME

-

Lap&Pol

-

GAND-E Lapping and Polishing System

The basic model is integrated with lapping and polishingSize:85*75*55cm -

GAND-T Lapping and Polishing System

Fully Enclosed Lapping and Polishing SystemSize:100*70*110cm -

GAND-P Lapping and Polishing System

Integrated lapping & polishing and cleaningSize:147*70*165cm -

CPI Chemical Lapping and Polishing System

Atomic-scale Surface PolishingSize:55*53*77mm -

Batch Lapping and Polishing System

Processes 48 × 2” wafersMulti-motor Drive System -

High Precision Double-Sided Lapping

The polishing slurry can be recycledHigh-precision surface profile control

-

-

CMP&Clean

-

CDP-400 Manual

可加工4寸及以下Size:90*65*150cm -

CDP-600 Manual

可加工6寸及以下尺寸:90*65*150cm -

ACDP-600 Manual

It can process 6 inches and belowSize:86*72*180cm -

CDP-800 Semi-Auto

可加工8寸及以下Size:110*145*220cm -

CDP-800 Fully Auto

带机械手臂运输尺寸:210*145*220cm -

Wafer Cleaning

Choice of various cleaning mediaBiphase cleaning and combined drying system

-

-

Bonding

-

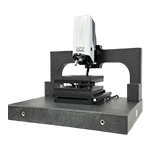

Microscope

-

Solution

-

About Us

marketing@mcfsens.com

marketing@mcfsens.com

Whats

Whats

Whats

Please Leave Us a Message on the Right

Please Leave Us a Message on the Right